Hopping along nicely

The Challenge

Established over a century ago and supplying brewers with the hops to design their own unique beers, our customer provides the full range of products, from whole hops through to processed hop products, such as pellets, extracts and oils. To ensure the highest product quality and prolong shelf-life, the company uses a process called gas flushing which requires nitrogen gas. Intrigued by the nitrogen generation cost saving information Maziak were promoting at a PPMA Show, they wanted to explore how they might benefit and reduce the high costs of multi-cylinder nitrogen packs.

The Solution

Maziak investigated the existing system and proposed two significant changes which led to even more significant cost reductions.

- Firstly the old system was using a mix of CO2 and N2 which was unnecessary and very costly.

- Secondly the gas was sourced from cylinders which can be costly and relies on timely deliveries and careful handling.

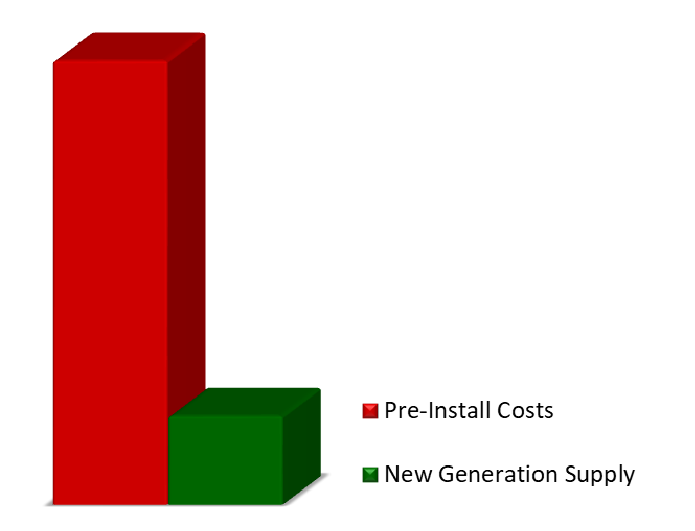

Maziak proposed an N2-only self-generation system guaranteeing Food Grade Nitrogen on demand at 20% of the cost.

In addition, Maziak’s innovative skid-mounted system offered a number of additional benefits, not least the fact that the system was built off-site and was installed on-site in less than a day, ensuring minimum disruption to production. The skid also provides future flexibility due to its compact, plug and play nature.

The Result

An impressive 80% reduction in costs with a payback period of under 2 years!